IoT - ESP-Everything!

(Click this line to jump to the story of the first prototype.)

My personal response to the weirdness that is ESP module form factors.

My introduction to ESP was the ESP-07.

It's an awesome module to play with. But it has a few issues.

Contents

The Issues

Issue #1: ESP devices run on 3.3V, not the ubiquitous 5V you can easily get by grabbing the nearest spare phone charger. This one's pretty simple. Put a 3.3V regulator in there. (I tend to grab the AMS1117-3.3. Cheap & easy...)

Issue #2: Every standard ESP module has a weird pinout at a weird pin pitch. Dunno why. They just do. Even the ESP-01 has a pain-in-the-ass pin layout. (but, at least it's on 0.1" spacing. Too bad it's designed to avoid breadboard compatibility...)

Issue #3: The most annoying one... To program an ESP chip, you have to hold gpio0 low during bootup or reset. Then you have to reset the board again to get out of programming mode. I get why they did it this way, but it's annoying.

Some available solutions

There are a number of cheap modules available that are basically either carriers for ESP modules or extensions of the ESP modules..

The LOLIN D1 mini is a favourite... It's "breadboard friendly" (as long as you don't mind it using up most of the width.) It has on-board regulation to run off 5V. It also has an onboard USB to Serial chip AND solves the gpio0 issue.

Sadly, most of these are in form factors that are not conducive to embedding in a finished project.

Also... I have an aversion to permanently installing a UART chip in devices that, once finished, will likely never need them again. When I'm working on a microcontroller project, I have a selection of UART modules handy to simply connect for programming. Afterwards, it's a redundant item.

So...

What I've done to try & solve a few of these issues

After discovering the ESP-M3, I determined that it would be nearly ideal for embedding into projects.

So I set out to design a carrier board for it.

& the whole bloody project got a little out of hand.

Basic Design requirements

- Power via random phone charger (or any other 5V source really)

- Make it hard to blow up with reverse power

- Programming header

- Compatible with the typical Sonoff header would be good

- Capable of automatic mode selection

- Breakout ALL available gpio pins from the module

- Putting them in some sort of logical order would be awesome

- Include 3.3V and GND pins for all io pins

- Small enough to drop into a PLASTIC North American electrical box

- Actual mounting holes!

The Building Blocks

Power

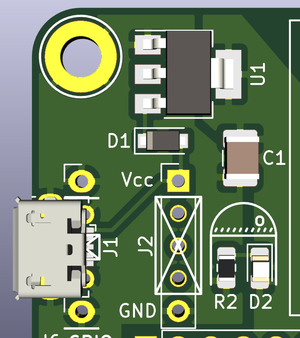

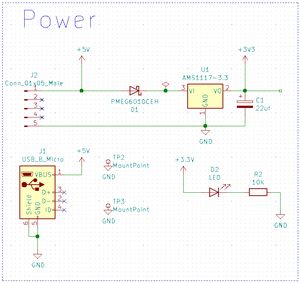

- Input:

- Directly soldered USB-micro connector (J1)

- My favourite USB breakout board (J2) J2 is basically positioned on the board such that using the breakout instead of soldering a connector directly to the board leaves the USB connector in the same spot, just 1.5 mm higher.

- Direct wiring (J2)

- Reverse polarity protection (D1)

- Note: The (nearly invisible) stripe on the diode should be to the left when installed. (towards the D1 marker)

- Regulation (U1 & C1)

- Minimal... AMS1117 & a tantalum capacitor for a bit of smoothing.

- Note: The stripe on C1 goes up. (towards U1)

- Indication (R2D2) :P

- When I initially put a power LED on board with its resistor, KiCAD generated the annotation... It went from there...

- Note: The cathode (- side) of D2 goes up. (towards R2D2s head) Which puts the "T" shape on the bottom of the part upside-down...

Assembly & Testing

- J1

- Should have 5v at pin-1 of J2 if you connect to a USB source

- D1

- Diode test (common on U1 & + on Vcc) = 0.211v

- U1

- Should have +3v3 from ground to any 3v3 point on the board

- C1

- This tantalum cap should NOT explode if you connect a USB source :O

- R2D2

- D2 should light up if you connect a USB source

Programming

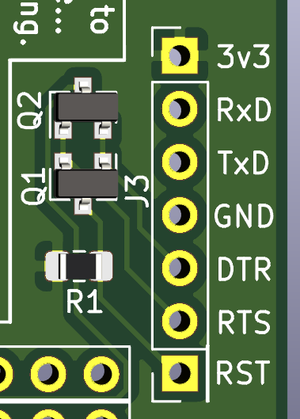

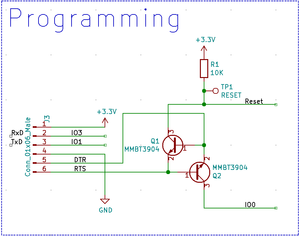

- Header (J3)

- Pins 1-4 are an exact match for the most common layout used on Sonoff devices.

- Pins 5 & 6 are used (with an appropriate USB-Serial adapter to enable the automatic mode selection

- RST is actually a test point & should be just another pin on J3. But, I didn't originally plan to put it directly inline with J3... so...

- Automatic mode selection (Q1 & Q2)

- This idea was shamelessly stolen from the D1-mini

- For flashing from PlatformIO, add

upload_resetmethod = nodemcuto your platformio.ini file

Testing

Using a DMM in Diode-Mode, measure from RST to RTS & DTR. Then do the same from GPIO0. (by "from" & "to", I mean put the common lead of your meter on the "from" point & the positive lead on the "to" point...)

- RST

- RTS ~= 0.8v

- DTR ~= 0.5v

- GPIO0

- RTS ~= 0.5v

- DTR ~= 0.8v

The numbers might not be exact depending on how your meter does diode-mode. But here should be SOMETHING across those transistors.

I/O

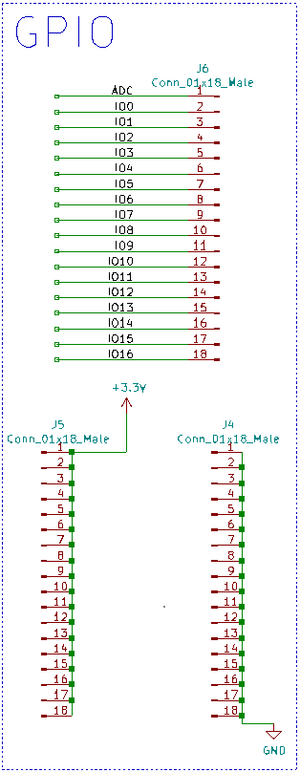

- GPIO breakout (J6)

- The ESP8266 (& ESP8285) have 17 GPIO & 1 ADC available. Therefore, I've placed an 18 pin header for I/O on the board.

- Power for sensors etc. (J5)

- Obvious once you look at the board... 18 pins...

- Ground for sensors etc. (J4)

- Obvious once you look at the board... 18 pins...

You will notice that ALL of the boards have the full set of I/O pins. On some (most) of the boards, you'll see (at least on the board views & renders) that some of the GPIO, 3v3 & GND sets are crossed out. The GPIOs are not all broken out on all modules. But, I've left the pin positions in to keep all the boards compatible with each other.

The Module Carrier

- All the empty space on the board... :P

A little extra about the board designs

While designing these boards, it has come to my attention that some of the default footprints in KiCad truly suck for hand soldering. So I've put in the effort to learn how to edit footprints...

Also, sometimes you might just need to create your own symbol libraries...

Eventually I'll even learn to create my own parts in 3D for the 3D board view...

BOM

- U1

- AMS1117-3.3

- Q1, Q2

- D1

- PMEG6010CEH

- DIODE SCHOTTKY 60V 1A SOD123F

- D2

- LG R971-KN-1

- LED GREEN DIFFUSED 0805 SMD

- C1

- TAJB226M010RNJ

- CAP TANT 22UF 20% 10V 1411

- R1

- CRCW080510K0FKEA

- RES SMD 10K OHM 1% 1/8W 0805

- R2

- CRCW08054K70FKEA

- RES SMD 4.7K OHM 1% 1/8W 0805

- or

- CRCW08052K20FKEA

- RES SMD 2.2K OHM 1% 1/8W 0805

- J1

- Molex 1050170001

- CONN RCPT USB2.0 MICRO B SMD R/A

- J2

- 5 pin header

- or... My favourite USB breakout...

- These work well too. & I've put in holes for the extra GND contacts for added strength. But, they do stick out a little bit past the end of the board.

- 5 pin header

- J3

- 7 pin header

- J4, J5, J6

- 18 pin header

The Resulting Set of Boards

- ESP-M3 Everything!

- (The original board)

- Built AND Tested... Successfully!

- ESP-01 Everything!

- ESP-07 Everything!

- Built AND Tested... (mostly) Successfully!

- Board needs a respin...

- ESP-01F Everything!

- ESP-12 Everything!

- ESP-?? Everything!

- (The generic board)

- ESP-SoC Everything!

- (The over board)

- ESP-Everything! Programming adaptor

- ESP-Else! (Carrier boards for other bits)